Introduction

Overview

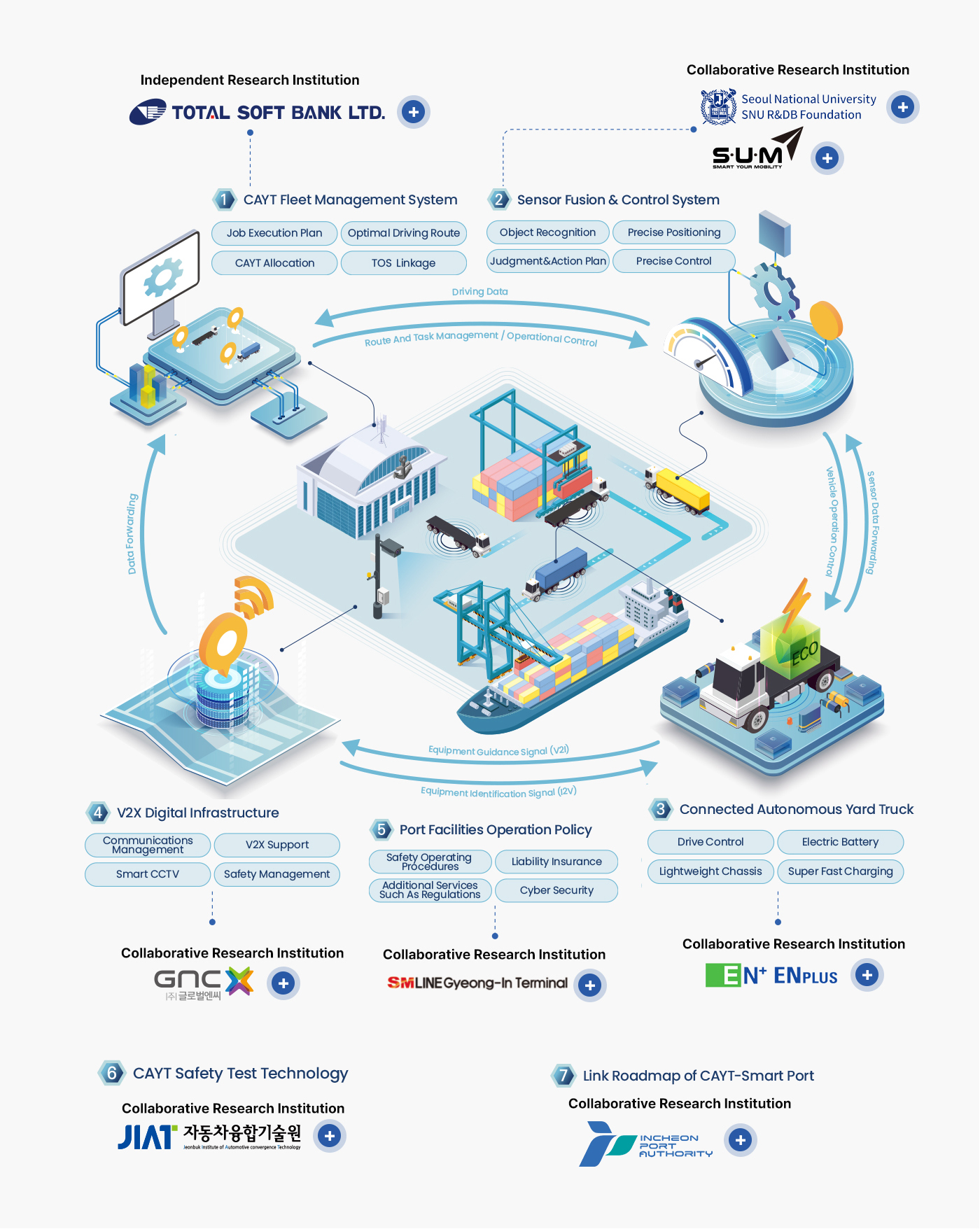

- CAYT fleet management system (FMS)

- An 'operation control system' that supports and manages 'CAYTs' for optimal driving by integrating with various systems within the port.

(* Terminal operation system (TOS), integrated control system, simulation system, etc.)

- CAYT sensor fusion and development of control system technology

- Development of a sensor system and recognition/judgment/control technology that minimizes blind spots in complex yard sections to secure operational stability.

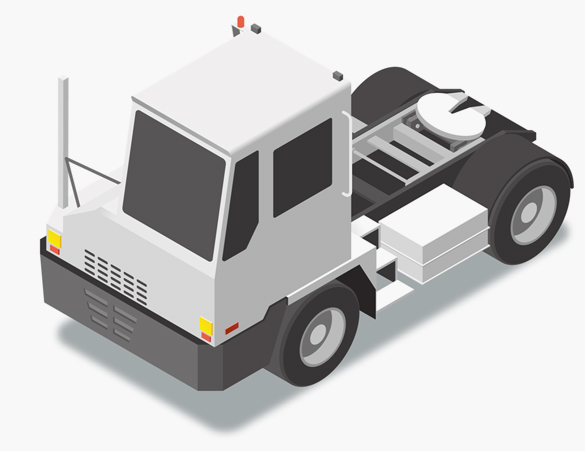

- Development of the CAYT

- Development of an electric yard truck that autonomously transports container cargo and integrates with other equipment and systems within the port.

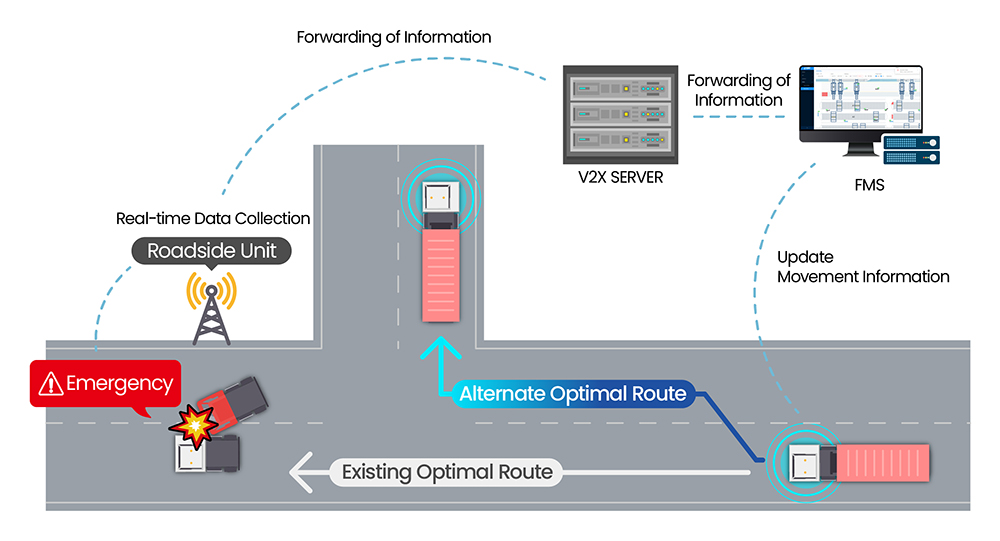

- V2X Digital Infrastructure

- Development of digital infrastructure to support the safe operation of CAYTs.

- Port facility operation policy and demonstration test

- Development of port-specific cargo transport equipment safety evaluation procedures and a vehicle performance evaluation; support fora secondary demonstration testbed and simulated verification evaluation

- CAYT safety evaluation technology

- Development of port-specific cargo transport equipment safety evaluation procedures and a vehicle performance evaluation; support fora secondary demonstration testbed and simulated verification evaluation

- Establishment of a CAYT-smart port linkage roadmap

- Establishment of a roadmap for smart port linkage between CAYT and Incheon Port for operation plan research.

- Development of a CAYT vehicle control algorithm

- Development of a control algorithm that reflects the dynamic characteristics of port/yard trucks to implement precise driving of CAYTs.

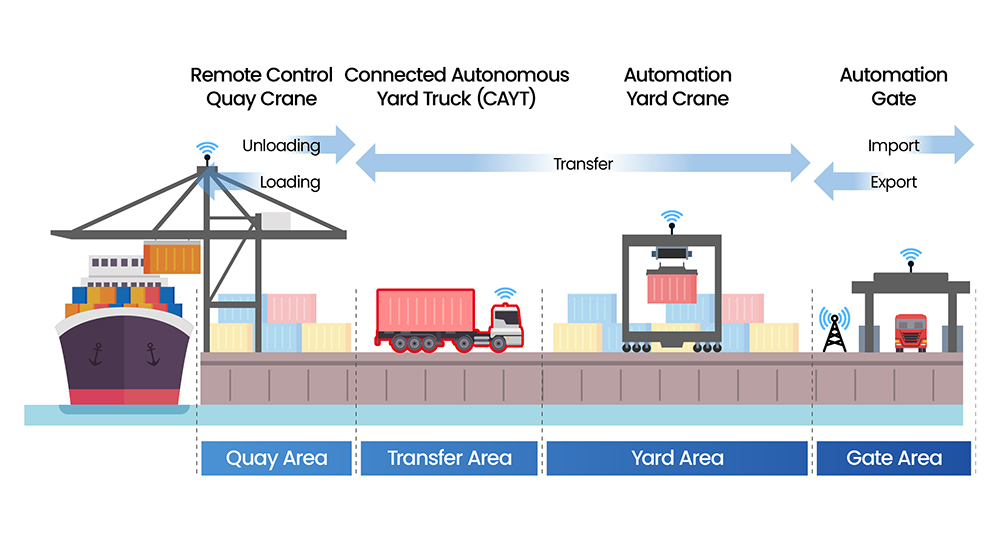

- What is the

CAYT system? - 'Connected Autonomous Yard Truck (CAYT)' and an 'Integrated Operations System'

that autonomously transports container cargo and integrates with other equipment and systems within the port.

- Business Name

- Development and demonstration of autonomous cooperative driving cargo transport equipment

- Research period

- 2022.04.01 ~ 2024.12.31 (2 years and 9 months)

- Final Goal

- Establishment 'Connected Autonomous Yard Truck (*Level 4)' and an 'integrated operating system' to improve cargo transport efficiency and enhance the competitiveness of ports.

- Detailed Goal

-

- Development of port-specific autonomous cooperative driving and operation technology

8 CAYT vehicles with Lv. 4 autonomous driving technology (new/remodeled)

- Development of a control system and digital infrastructure technology for establishing automated ports

Simultaneous control of 100 units, 30% increase in container transportefficiency

- Development of autonomous cooperativedriving-based transportation system demonstration technology

Performance validation (SaeMangum Proving Ground, SMPG), demonstration verification (Seoul National University Siheung Campus, SM LINE Gyeong-In Terminal) - Secured in-port driving records of 10,000hr and 80,000km

- Development of port-specific autonomous cooperative driving and operation technology

Vision & Goal

Creation of a Proprietary Technology Brand

Domestic Standards & Leading the Global Market

International Standards & Diffusion of Technologies

Promotion of Relevant Systems in Ports

Reduction of On-site Safety Accidents

Enhancement of Work Quality for Port Workers

Precision (Errors)

Control Capacity

of the FMS System

Software Aspect

Improvement of Transportation Efficiency

Transportation Efficiency

Yard Truck (Level 4)

- Manned Yard Truck Role-Oriented, Inefficient System

- Outdated Infrastructure Non-Digital Environment

- Lack of Port Standards Non-Standard

- Inefficient Transportation System Human-Centric Transportation System

- Poor Working Environment Numerous Port Accidents

- Connected Autonomous Yard Truck

- Vehicle-to-Everything(V2X) Digital Infrastructure

- Establishment of International Standards

- System-Centric Continuous Transportation System

- Establishment of an Accident Prevention System

- Adopting Global Standards, Acquiring Certification and Intellectual Property Rights and Developing a Commercial Product

- Port-specific CAYT and its operation technology

- Preventing Port Accidents, Establishing Digital Infrastructure and Utilizing Testbeds

- Digital infrastructure technology for establishing automated ports

- Improving Container Transportation Efficiency and Stevedoring Productivity, Leading the Global Market

- Fleet management system (FMS) for establishing automated ports

R&D Plan

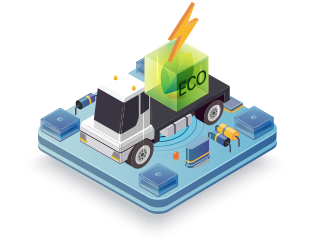

01Development of the CAYT

Development of an electric yard truck that autonomously transports container cargo and integrates with other equipment and systems within the port.

Development of an electric yard truck that autonomously transports container cargo and integrates with other equipment and systems within the port.

- Electric battery

- An electric battery containing oxide,which is very safe, that is suitable for industries requiring high safety and high output within a short timeframe, with no performance degradation or discharge in cold environments as low as –35℃.

- Electric Drive Motor

- Power pack for the electric propulsion system.

- Chassis&5th wheel lifting system

- For reduced vibration during operation, a rear-wheel drive axle and independent multi-stage suspension for the fifth wheel have been implemented.

- Autonomous sub controller

- Controls the CAYT’s acceleration/deceleration/steering device according to the recognition and judgment of the upper controller.

- BCU(Brake Control Unit)

- Lever structures or chain mechanisms have been applied to the existing brake systems to optimally control deceleration.

- ACU(Accelerator control unit)

- Signals from the existing accelerator position sensorsare used to control the signal strength and output.

- ESCU(Electric steering control unit)

- The ESCU precisely controls the movement of the steering wheel using an electric motor.

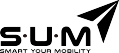

02Development of CAYT sensor fusion &control system technology

Development of a sensor system and recognition/judgment/control technology that minimize blind spots in complex yard sections to secure operational stability.

Development of a sensor system and recognition/judgment/control technology that minimize blind spots in complex yard sections to secure operational stability.

03Development of CAYT vehicle control algorithm

Development of a control algorithm that reflects the dynamic characteristics of port/yard trucks to implement precise driving of CAYTs.

Development of a control algorithm that reflects the dynamic characteristics of port/yard trucks to implement precise driving of CAYTs.

<R&D of algorithms for yard truck control model generation and perception processing>

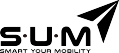

04V2X Digital Infrastructure

Development of digital infrastructure to support the safe operation of CAYTs.

Development of digital infrastructure to support the safe operation of CAYTs.

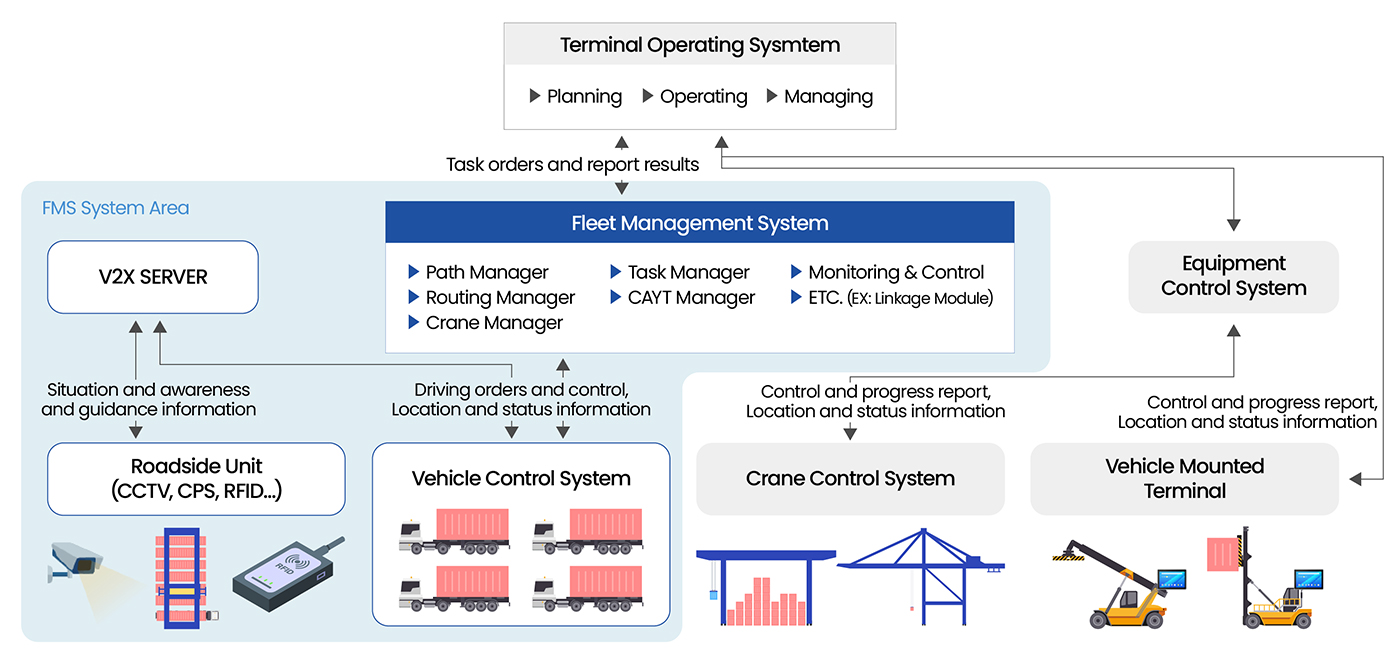

05CAYT fleet management system (FMS)

An operation control system that supports and manages the optimal driving of CAYTs by integrating with various systems within port.

An operation control system that supports and manages the optimal driving of CAYTs by integrating with various systems within port.

06CAYT safety evaluation technology

Development of port-specific cargo transport equipment safety evaluation procedures and a vehicle performance evaluation; support fora secondary demonstration testbed and simulated verification evaluation

Development of port-specific cargo transport equipment safety evaluation procedures and a vehicle performance evaluation; support fora secondary demonstration testbed and simulated verification evaluation

1. Development of safety evaluation procedures and a vehicle performance evaluation for the CAYT

- [Safety Assessment Procedure]

-

- 01

System Specification Analysis / Definition

- 02

Development of evaluation scenarios

- 03

Development of test procedures

- 01

- [Performance Evaluation Items]

-

- Main specifications: Total vehicle weight, size, maximum speed, braking distance, etc.

- Energy consumption efficiency: Comparative evaluation of battery energy consumption efficiency by measuring the running resistance and single charge distance.

- Electromagnetic compatibility: Support forelectromagnetic compatibility (EMC) testing and debugging, such as the identification of the EMI tendency and emission/susceptibility tests based on actual vehicles.

2. Support for a secondary demonstration test (SMPG) and precision evaluation of the CAYT control performance

- Support for a secondary demonstration test of the CAYT by simulating the port operation and working environment.

- HD map image of the driving test site added to support the demonstration test.

-

SaeMangum Proving Ground(SMPG) (SMPG)

SaeMangum Proving Ground(SMPG) (SMPG)

-

SaeMangum Proving Ground(SMPG) HD Map

SaeMangum Proving Ground(SMPG) HD Map

07Establishment of a CAYT-smart port linkage roadmap

Establish a roadmap for smart port linkage between CAYT and Incheon Port to derive the operation plan.

Establish a roadmap for smart port linkage between CAYT and Incheon Port to derive the operation plan.

- Year 1

-

Securing of Global Competitiveness in Ports

- Research on a smart port-CAYT linkage operation plan

- Investigation of domestic and international laws/regulations and overseas cases

- Establishment of an operation manual (general)

- Year 2

-

CAYT-Incheon Port Economic/Environmental Benefits Analysis

- Simulation of increased transportation at Incheon Port due to CAYT operation

- Analysis of the carbon reduction amount at Incheon Port

- Year 3

-

Establishment of a CAYT Operation Manual

- Research of the existing Port Workforce Retraining Program (4IR job conversion) - associated with the Human Resources Development Service of Korea

- Establishment of an operation manual (detailed)

- Deliverables goal s

-

- CAYT-Smart port linkage roadmap

- Incheon Port cargo transportation increase and carbon reduction analysis report

- CAYT operation manual (general, detailed)

- 4IR Port Workforce Retraining Program (draft)

- Core Project

-

- Datafication of port resources

- Development of a big data platform

- Establishment of an automated port

- Realization of port logistics flow optimization

- Core Project

-

- Development of eco-friendly technology

- Development of an eco-friendly/energy platform

- Formation of renewable energy clusters

- Implementation of eco-friendly energy independence

- Core Project

-

- Development of safety/security-based technology

- Development of safety/security integration platform

- Establishment of a Smart Safety Center

- City-linked safety management system

08Port facility operation policy and demonstration test

Development of port-specific cargo transport equipment safety evaluation procedures and a vehicle performance evaluation; support

fora secondary demonstration testbed and simulated verification evaluation

Development of port-specific cargo transport equipment safety evaluation procedures and a vehicle performance evaluation; support

fora secondary demonstration testbed and simulated verification evaluation

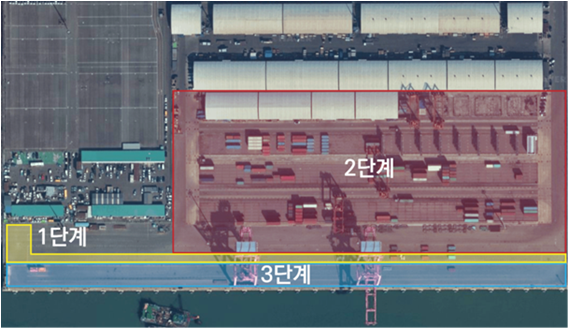

1. Definition of the testbed environment and support for the third demonstration test (testbed safety management & maintenance)

- Level 1 Test: Lane-free block area

- Level 2 Test: Yard freight station area

- Level 3 Test: Quay wall area

- The test schedule can be flexibly adjusted (considering the main line schedule and testbed situation)

2. Preparation of a CAYT operation manual and demonstration test scenarios

- Preparation of an operation manual establishing the standards for the application of CAYTs in ports

- Preparation of demonstration test scenarios to verify the feasibility of commercialization, including safety/driving performance evaluations, etc.

3. Manufacture of a CAYT-specific chassis

- Installation of power cables and brake systems for recognition of the surrounding environment

- Modifications to overall inspection for wheel and tire condition, etc., for precise recognition of heavy cargo units

Background

- Automation-related technology development is increasing in the port equipment industry to improve operational efficiency and safety and reduce labor costs

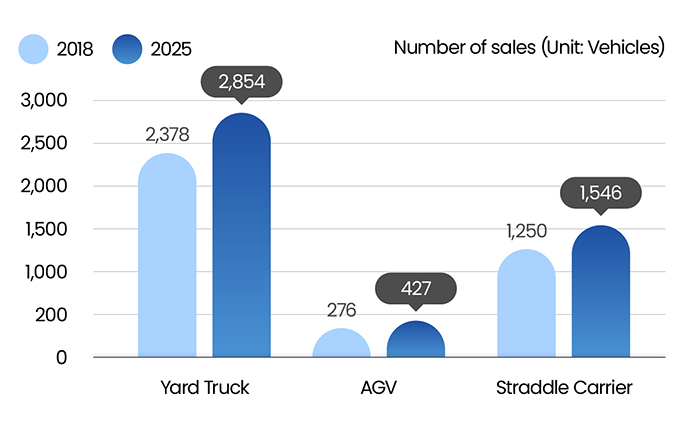

- In 2018 2,378 yard trucks and 246 AGVs utilizing autonomous driving technology were sold, and sales are forecasted to grow at an annual average rate of 2.9% from 2019 to 2025, reaching up to 2,854 and 427 units, respectively, in 2025.

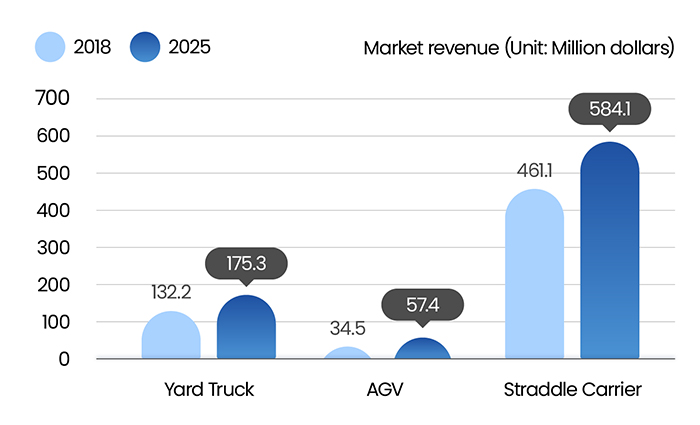

- The market revenues of yard trucks and AGVs are expected to grow at annual average rates of 4.6% and 9.2%, respectively, from $132.2 million and $34.5 million in 2018 to $175.3 million and $54.7 million in 2025.

- Automated guided vehicles (AGVs) transport containers autonomously by relying on floor sensors installed between container cranes and freight stations.They have the highest growth rate of 7.8% in the smart port equipment market share.

Global market sales status and forecast for container transportation equipment

Global market revenue status and forecast for container transportation equipment

Source : Global Market Insights(2019), Port Equipment Market Report 2015

- Korea urgently needs more higher value-added ports as the added value of Busan Port is approximately KRW 5.8 trillion, on 34 ~ 40% that of advanced overseas ports. It is necessary to optimize logistics flow and strengthen the competitiveness of services in ports through Fourth Industrial Revolution(4IR) technology.

- Container cargo transportation efficiency can be enhanced at a lower cost by developing automation for “yard trucks (YTs),” where there is almost no domestic involvement in technology development, and by implementing aprocess automation/optimization system (before transporting the cargo)for domestic and overseas container docks.

- For the realization of autonomous vehicles with at least level 4 autonomous driving technology, the importance of autonomous cooperative driving based on infrastructure within the port has been further emphasized. In addition, HW/SW redundancy technology for the main functions (recognition, control, power, steering, brake system) is necessary.

- Safety and mobility can be improved through accident prevention by applying cooperative-intelligent transport systems (C-ITS) in ports.

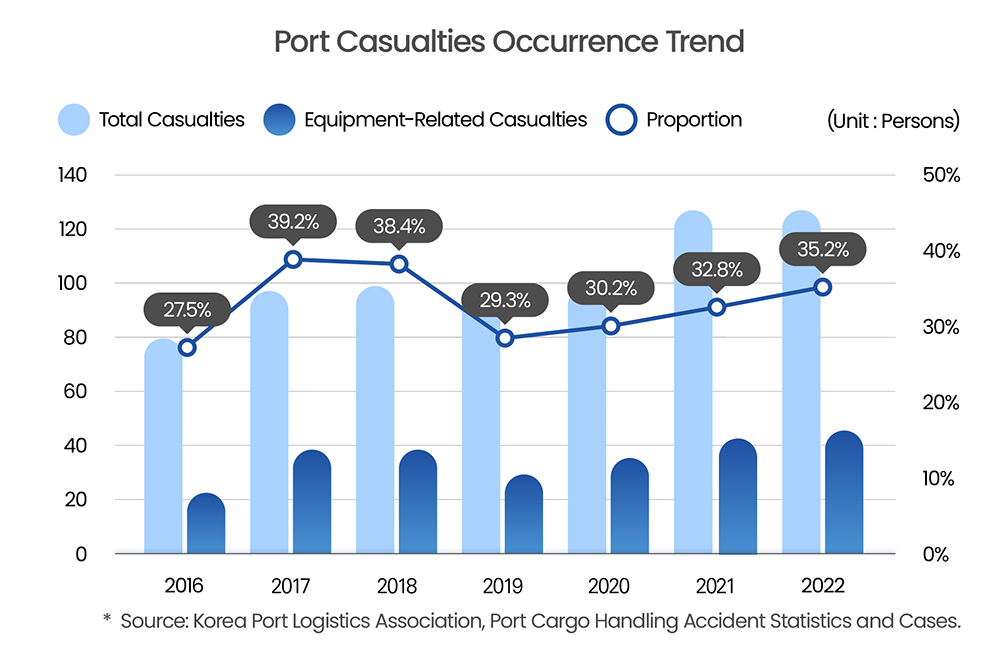

- The Ministry of Oceans and Fisheries announced 'Comprehensive measures to prevent accidents in port logistics' in 2019.

- The rate of disaster victims due to equipment in the port industry is 35~42%, meaning there remains a steady occurrence of accidents.

(Vehicle-vehicle/vehicle-worker collisions, drowsy driving, increased labor fatigue, etc.) - The importance of reducing risk factors for accidents is highly emphasized by applying accident prevention functions directly to the vehicles, such as an immediate brake & avoidance systemfor emergencies, and minimizing human intervention in port operations.

- The largest number of workers are involved in driving yard trucks that transport cargo in the port; however, due to the intensity of labor and the 24-hour operation, young workers are reluctant to engage in fieldwork, increasing difficulties in manpower supply.

- It is necessary to improve the labor intensity of manned yard truck drivers through the introduction of automation and to solve the issue of industry avoidance for smooth logistics.